GA-180W~250W ZIQI GA series compressor

power:180-250 Kw

Production:27.5-46.0 m3/min

Exhaust:0.7-1.3MPa

Drive mode:Flexibility Driven

Cooling method:air cooling

GA-180A ~ 250A screw compressors are designed, manufactured and tested according to strict standards. Two-stage compression, each stage of the scientific distribution of pressure and improve volumetric efficiency ZIQI two-stage compression injection screw machine at the same power, single-stage compression than the injection screw compressor 12% -18% of the gas. In other words, under the same gas compression, two-stage compression can reduce power by 15% on average compared to single-stage compression. Rotor and bearing force is small, with the rotor diameter, low speed, so the operation is more reliable.

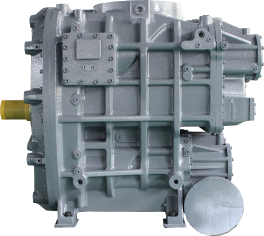

| Host: ·Low noise: a unique rotor type line, making the host low-speed low-grade vibration classification operation, effectively reducing the air flow pipeline vibration and reduce noise. · High reliability: superior pressure distribution, reduce bearing load, making the bearing life up to 150000 hours Unique rotor profile, making the yin and yang rotor height engagement, long service life compression stage, effectively reduce oil leakage, which helps to form oil film protection rotor ·Super energy-saving: Adopting superior pressure ratio distribution, greatly improving the compression efficiency Adopting inter-stage cooling, close to isothermal compression |  |

| Motor: ·The frame and the end cap of the motor are made of cast iron material so that the gap between the rotor and the spindle is uniform; ·Design speed, torque and operating parameters to meet the compressor load requirements; ·Designed with SKF heavy-duty bearings, greatly increasing the stability and life of the motor; ·High-efficiency motor with F-class insulation, B-class temperature rise, longer life, more able to adapt to harsh environments; ·The motor adopts the IP55 degree of protection of the motor, effectively prevent dust and water into the motor; |  |

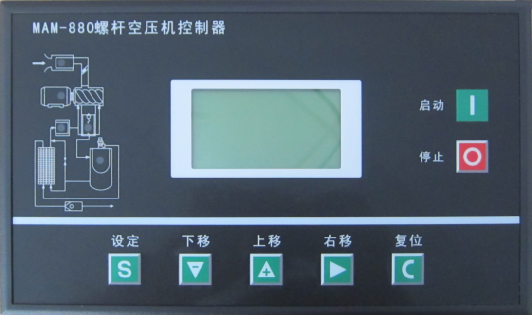

| Electrical control system: ·The main control components imported brand-name products, optimize the integration in one, high reliability, trouble-free running a long time; ·The use of integrated intelligent, intelligent higher programmable PLC, the most cost-effective way to control the operation of the entire unit; |  |

| Transmission: ·The motor and the host are equipped with an integrated gear drive system. ·Is effective, reliable and rugged design. ·Carefully selected high speed gears are mounted on the shaft of the motor and the main unit. ·Flexible coupling direct drive, the motor, the host into one, transmission efficiency, reliable operation. |  |

| Tubing: ·Selection of Italy Manuli high-pressure tubing, 5 times longer than ordinary tubing life, the use of Purple unique anti-lock technology, |  |

| Cooling System: ·Large area of high quality oil cooler and rear cooler. ·Extend the service life of lubricants, filters and seals. ·The use of a unique low temperature difference design, with high temperature and high humidity environment for the design premise, suitable for any regional environment. |  |

| Airway system: ·Intake filter with imported filter, dust removal effect of 99.9%, to ensure that the compressor host effective dust; ·Intake valve assembly specially designed servo cylinder, with check function, no need to install oil check valve and oil valve; ·Unique external air pre-filter, to keep the machine clean, extend the maintenance cycle, can easily disassemble and clean up; |  |

| Mode | Air Pressure(Mpa) | Air Displacement(m³/min) | Power(kW) | Noise(dB(A)) | Dimension(mm) | Weight(kg) | Exit Diameter(mm) | Cooling water inlet pipe diameter(luch/mm) | ||

| L | M | H | ||||||||

| GA-180W | 0.7 | 34.5 | 180 | 77±2 | 3100 | 1800 | 2065 | 3700 | 80 | 50 |

| 0.8 | 32.0 | |||||||||

| 1.0 | 30.0 | |||||||||

| 1.3 | 27.5 | |||||||||

| GA-200W | 0.7 | 37.5 | 200 | 78±2 | 3250 | 1900 | 1965 | 4010 | 80 | 50 |

| 0.8 | 35.5 | |||||||||

| 1.0 | 32.5 | |||||||||

| 1.3 | 29.0 | |||||||||

| GA-250W | 0.7 | 46.0 | 250 | 78±2 | 3250 | 1900 | 1965 | 4610 | 100 | 50 |

| 0.8 | 44.5 | |||||||||

| 1.0 | 41.0 | |||||||||

| 1.3 | 37.0 | |||||||||

download123123123123123132132